Industry Insight: Innovation in Global Aerospace

Airbus’ ink jets

Astonishing 3D printing or Additive Layer Manufacturing has revolutionized the design and printing of airplane liveries at Airbus. Now the European aircraft manufacturer is using the technology to build entire aircraft, chief correspondent, Tom Ballantyne, learnt at Airbus’ recent Innovation Days in Hamburg.

July 1st 2016

THOR can’t really be described as a commercially viable aircraft, but it has flown. The letters stand for Test of High-tech Objectives in Reality and it is one of the more recent developments in Airbus’ drive to find new and more efficient ways of building aircraft. Read More »

|

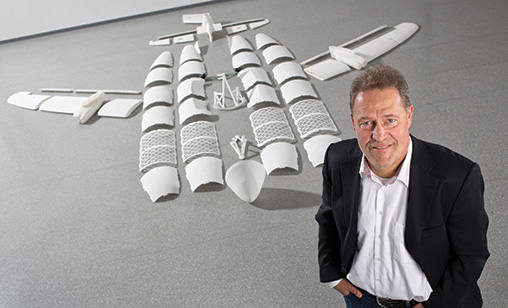

It is, in fact, the world’s first 3D printed aircraft and it is one of the more recent developments in Airbus’ drive to build its aircraft more efficiently. So far, THOR it is only a drone with a wingspan of four metres, but Airbus believes the miniature flying machine is a major milestone in aerospace technology.

The airplane, which took four weeks to build from parts entirely 3D printed from aluminum powder, is scheduled to complete 16 flights in 2016.

But building experimental printed planes is not the end of the story. Like its U.S. rival, Boeing Commercial Airplanes, Airbus is 3D printing many of the parts it uses to build its jets.

A bionic cabin bracket “printed” from titanium powder made its first flight in an A350XWB on June 20, two years ago. Airbus also has manufactured a cabin partition printed from aluminum powder.

The result is a panel that is 50% lighter than a normal panel and a component that is planned to be trialled on an Airbus test aircraft in the final quarter of this year. Airbus head of emerging technologies and concepts, Peter Sander, said ALM represented an alternative to the production processes of milling, melting, casting and precision forging.

It also saves resources. It produces 5% in waste material compared with 95% from conventional machining. It also facilitates more efficient production of detailed, highly complex bionic parts.

The combination of ALM and bionic design creates parts that are up to 55% lighter than in previous manufacturing processes and improve output times by up to 90%. It is expected that printed aircraft parts could reduce costs by 75% overall and allow Airbus to achieve more rapid analysis of aircraft components.

Airbus’ commitment to new 3D printing technology is revealed by its investment in the “Aerospace Factory” in Munich, Germany, which is being developed with several industry and research partners.

Based at the interdisciplinary Ludwig Bolkow Campus Ottobrunn/Taufkirchen, south of Munich, it will research and apply new 3D printing materials and production methods for the aerospace industry, with a focus on developing lightweight, cost-efficient and structurally complex propulsion systems.

With the goal of producing 3D mission control propulsion systems, each partner will contribute its expertise and resources from component design, metal powder and materials production to additive manufacturing, process simulation and quality control.

|

The materials research laboratory belonging to Airbus Group Innovations, the group’s central global research network, is a 4,500 square meter facility that will house 65 experts. They will apply 3D printing with other advanced manufacturing technologies to develop robust and environmentally friendly materials for aerospace components.

Airbus recently announced plans to 3D print half of its future airplane fleet and investing in the e Aerospace Factory and materials research laboratory is a major step towards that goal.

In a separate project, engineers from Airbus’ paint shop in Hamburg have developed an industry first of “direct printing” of large and complex liveries on aircraft vertical tail planes (VTPs).

Painting an aircraft takes up to two days. Airbus’ head of the A320 Family Paint shop, Ralph Maurer, said the common practice in the industry ranged from adhesive film to airbrush and stencil techniques. They have a few advantages and several disadvantages compared with new 3D printed technology.

The new process uses industrial inkjet printers that decorate VTPs faster, more efficiently and with finer detail than traditional methods. “This is particularly interesting for customers whose liveries include photo-realistic motifs, complex patterns or modern art paintings with color gradients,” Maurer said.

Britain’s Thomson Airways was the launch customer for the new livery technology. The direct printer functions much like a traditional model, using a special inkjet head with nozzles that spray the three basic colours of cyan, magenta and yellow as well as black onto the VTP.

The ink exhibits good adhesion properties and bonds well onto existing aviation-specific paint systems. It is applied on the base-coat of the VTP and sealed with a clear coat. “This ensures good durability in extreme temperatures, ultra-violet radiation and erosion that aircraft paint must tolerate. Airbus foresees a time when an inkjet printer will be able to sweep across an aircraft painting its entire livery from nose to tail.